Services without compromise

The electrician wants to chase the wall, the plumber wants a straight drop, and the builder does not want to weaken a panel on site. Self builders worry about holes in a new shell, while turnkey clients expect a clean finish with no rework. When service routes are planned and sealed, the envelope stays strong and airtight. UltraSIPS aligns service zones with the layout drawings so penetrations are treated as details, not last-minute cuts.

The golden rule

Treat service runs like structure. If you cut without a plan, you lose both strength and airtightness.

Working with other trades

MEP coordination is a team sport. Builders, electricians, plumbers, and HVAC designers must agree on routes before panels arrive.

Comparison

Coordination priorities

Decide these before the shell is closed.

Electrical

- Chase locations and depth

- Switch and socket positions

- Avoid splines and load paths

Plumbing

- Vertical drops planned

- Avoid large bore cuts through structural zones

- Confirm wet room locations early

HVAC

- Duct routes and plant location

- Supply and extract balance

- Service void requirements

Envelope sealing

- Penetration gaskets and tapes

- Airtightness sequence

- Testing plan

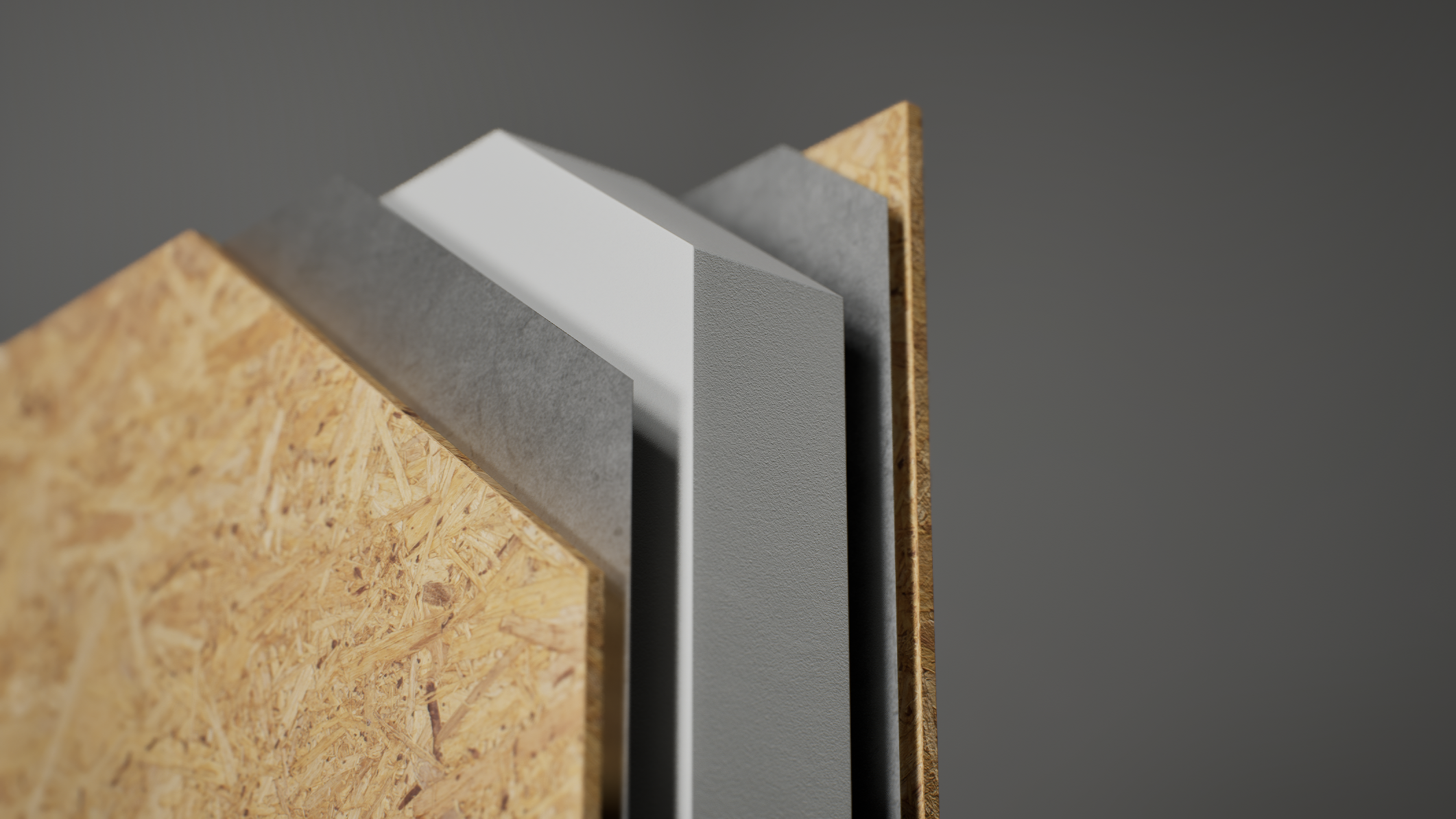

Service cavities vs chases

There are two main strategies:

- Service cavity: add a battened void inside the panel.

- Pre-planned chases: factory-routed channels for wiring.

Comparison

Cavity vs chase

Choose the route that protects the structure.

Service cavity

- No cutting into panel core

- Flexible for late changes

- Adds depth to internal lining

Factory chases

- Clean and efficient

- Best for repeatable layouts

- Needs early coordination

Label your chase locations

Clearly label chase zones on the drawings and the panels. This prevents random cutting and keeps trades aligned.

Electrical in SIPs

Electrical runs should avoid splines and concentrated loads. Where possible, keep wiring in service zones or cavities.

Plumbing chases

Large diameter pipes should not cut through structural cores. Use planned drops and service voids.

Roof applications and shielded cables

Roof panels often carry lighting and PV wiring. Use shielded cable or conduit and keep routes clear of structural joints.

Penetrating the envelope

Every penetration must be sealed. Use grommets, tapes, and sealants compatible with the panel skin and internal lining.

HVAC analysis and design

Airtight SIP shells need a ventilation strategy that matches the build. MVHR is common in the UK, but even simpler systems require planned supply and extract routes.

Humidity control

Tight buildings trap moisture if ventilation is undersized. Balance extract in kitchens and bathrooms, and avoid excessive indoor humidity during first heating.

Ventilation strategies

Comparison

Ventilation strategies

Match the strategy to the shell and client expectations.

MVHR

- Best for airtight SIP shells

- Recovers heat while ventilating

- Needs planned duct routes

MEV

- Simpler than MVHR

- Works with good background ventilation

- Lower heat recovery

Passive vents

- Lowest cost

- Harder to control in winter

- Not ideal for very airtight shells

Conditioned crawlspaces

If you use a crawlspace, treat it as part of the envelope. Insulate and seal it properly to avoid moisture and cold floors.

Testing the envelope

Airtightness is measured, not assumed. Plan for blower door testing and duct leakage checks.

Comparison

Testing the build

Testing proves performance and catches leaks early.

Blower door test

- Measures air leakage at 50 Pa

- Finds leaks before finishes

- Required for compliance

Duct pressure test

- Checks HVAC leakage

- Improves system efficiency

- Avoids future call-backs

Plan for sealing

Write a sealing plan for every penetration and joint. Decide who seals what, and when.

MEP checklist

- Plan service zones early.

- Use cavities or factory chases.

- Label chase locations.

- Seal every penetration.

- Coordinate MEP with layout drawings.

- Plan HVAC and humidity control.

- Schedule airtightness testing.