The shell-up day

A small crew is on site, the builder wants pace, the self-builder wants a safe, predictable sequence, and the turnkey client wants the shell up before the weather turns. One panel out of order can stop the crane and reset the day. When set-out is accurate and every joint is sealed as you go, the shell feels like a kit that clicks into place. UltraSIPS provides a repeatable install sequence so crews move fast without cutting corners.

Before you lift

The install starts on paper. Confirm layout drawings, panel numbering, and the lift sequence before the crane turns up.

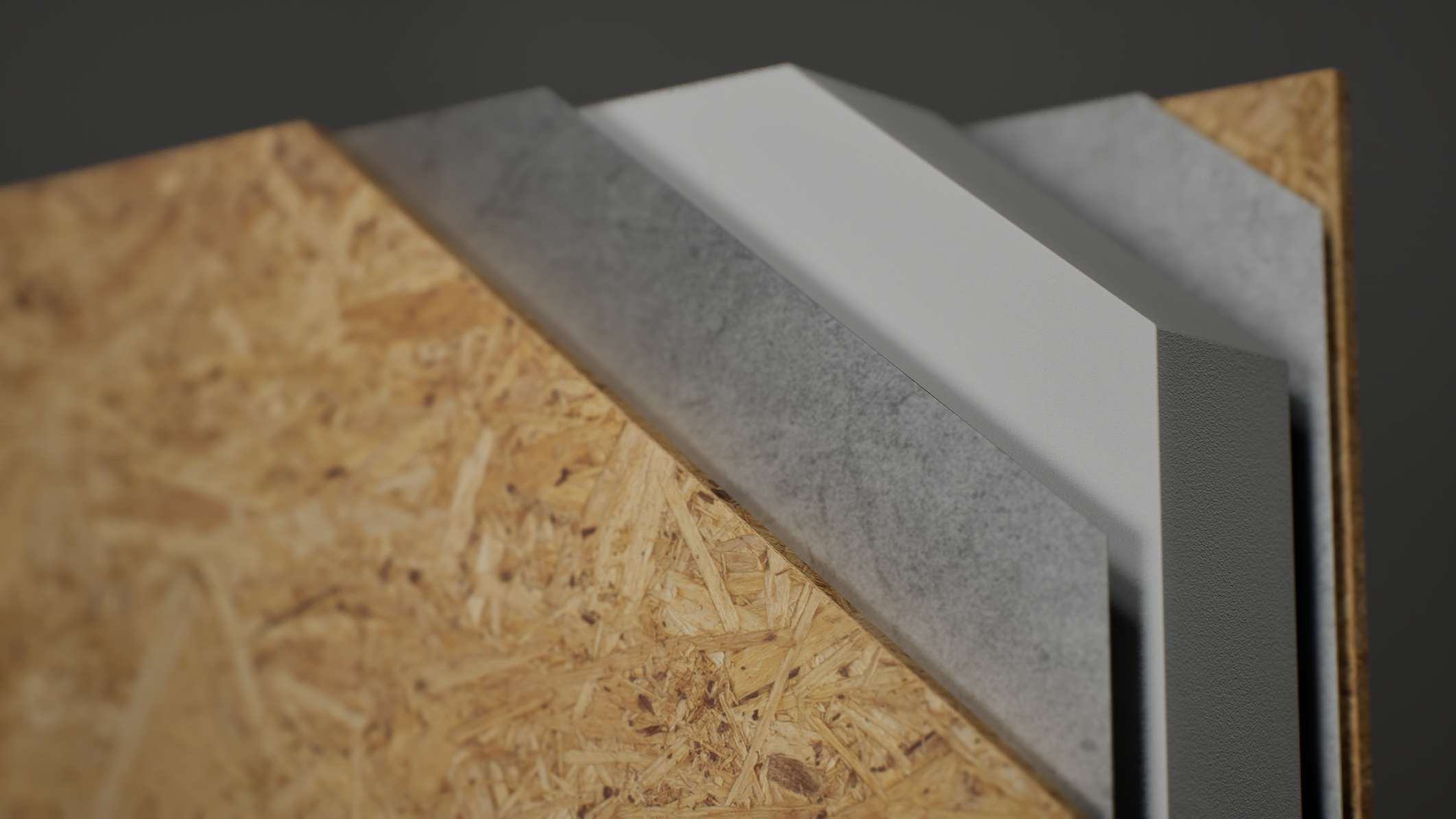

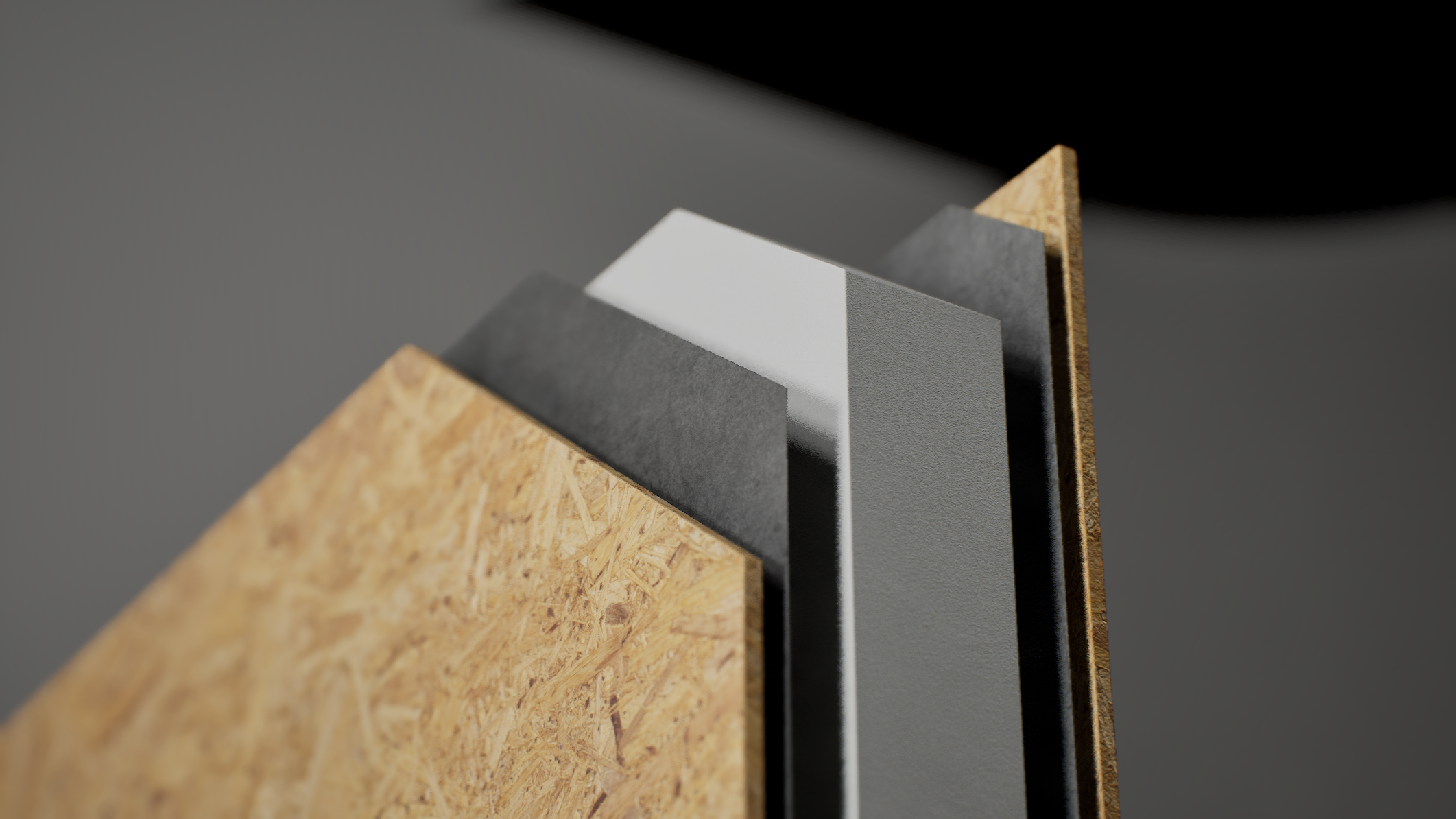

Comparison

Pre-lift checks

The fastest installs start with these checks.

Layout drawing check

- Panel numbers and order

- Openings and header details

- Spline types per joint

Panel prep

- Lift points confirmed

- Sealant and tape ready

- Bracing and fixings staged

Rigging plan

- Crane signals agreed

- Safe zones marked

- Tag lines prepared

Crew roles

- Install lead set

- Banksman and fixer assigned

- Quality check responsibility clear

Step 1: Set out the base

Confirm sole plate lines and check diagonal measurements. Dry-fit where possible to confirm panel order.

Step 2: Position the first panel

The first panel sets the line. Plumb it carefully and brace it before continuing.

Step 3: Join panels with splines

Use the specified spline type, apply sealant, and fix per schedule.

Step 4: Seal every joint

Airtightness depends on disciplined sealing. Do not skip joints, even if finishes will cover them.

Step 5: Roof panels and capping

Roof panels often go up after walls are braced. Use capping timbers and check alignment before final fixings.

Where to start

Start at a straight run with a clear corner so the install can stay square. Work from fixed reference points, not moving edges.

Floor system coordination

If you are tying SIP walls to a floor system, confirm bearing points and hangers before the wall panels arrive. Misaligned floors slow everything.

Other trades and sequencing

Keep plumbing, electrics, and glazing aligned with the SIP install. Trade clashes happen when services are not pre-planned.

Special tools that save time

- Laser level for long wall runs

- Adjustable braces and temporary props

- Sealant guns and tape rollers

When to apply SIP tape

Tape should be applied once joints are fully seated and sealed. Do not tape over wet or contaminated surfaces.

Efficiency and labeling

Panels should be staged in install order with labels visible. If labels are hidden, you will lose time and risk panel damage.

Order of construction

Wall panels first, then roof panels, then capping and final fixings. Follow the layout drawings and do not skip the bracing step.

Installation checklist

- Confirm set-out and brace the first panel.

- Install splines with sealant and fixings.

- Seal every joint as you go.

- Check plumb and square before roof panels.

- Apply tape after joints are seated.

- Confirm labels match the install sequence.