Finishes that protect

A turnkey client wants a premium look, a self-builder wants a finish they can maintain, and a builder wants zero call-backs from hidden moisture. Poor flashing and missing cavities are where good SIP shells fail. When cladding is detailed with a ventilated cavity and every opening is flashed properly, the envelope stays dry and stable. UltraSIPS focuses on water-first detailing so the finish protects the structure, not the other way around.

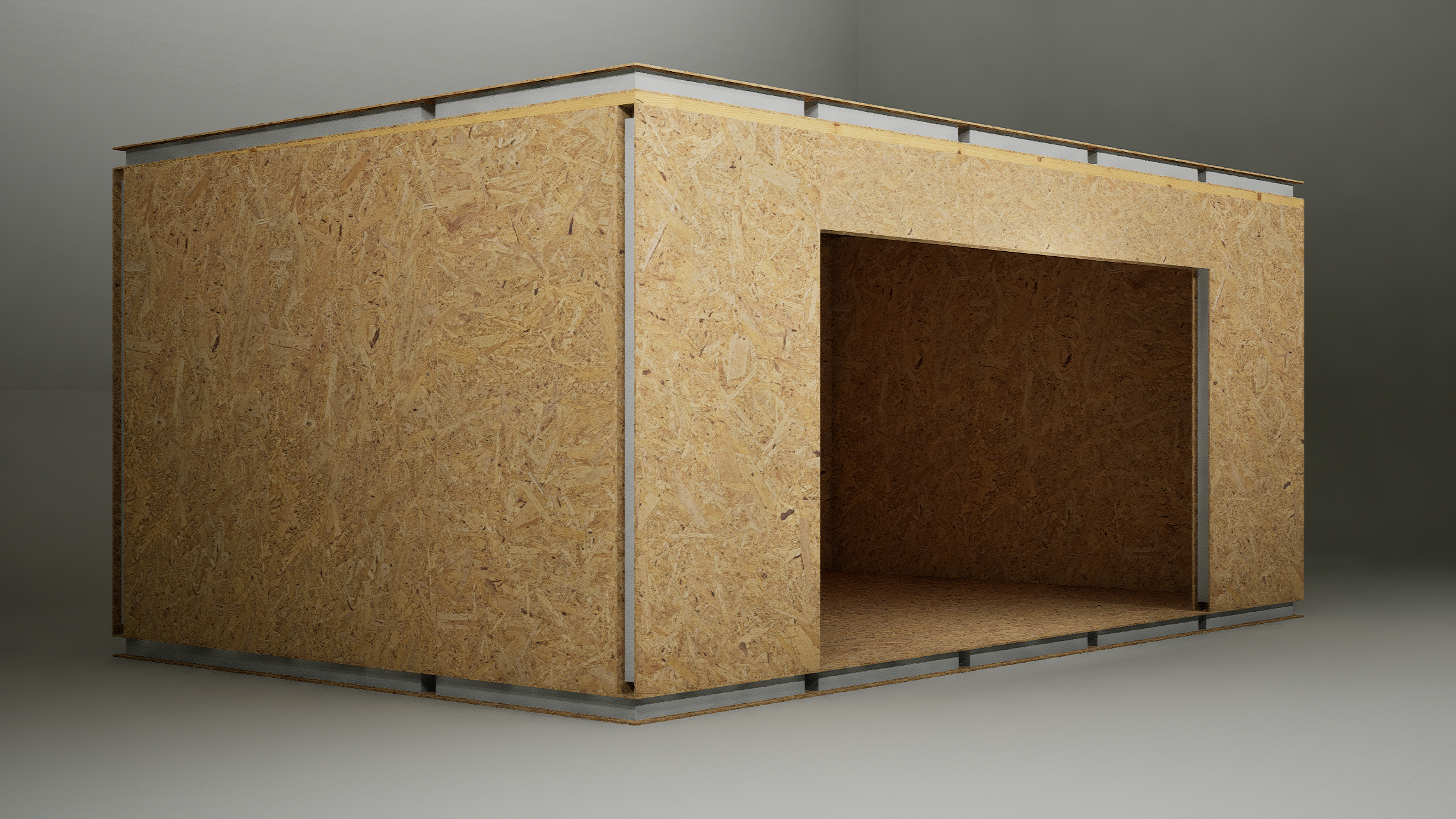

What covers the SIP envelope

Finishes are not just aesthetics. They are the layers that keep water out, control drying, and protect the panel edges.

Comparison

Envelope protection layers

Each layer has a specific job.

Cladding or outer skin

- Primary weather protection

- Defines appearance

- Needs ventilation behind

Rainscreen cavity

- Allows drainage and drying

- Reduces moisture trapping

- Critical in UK climates

Membranes and tapes

- Seal openings

- Control vapour movement

- Protect panel edges

Interior linings

- Fire resistance

- Airtightness backup

- Finish-ready surface

Exterior cladding

Common SIP-compatible finishes include timber, composite, brick slips, and render. The key is a ventilated cavity to manage moisture.

Comparison

Cladding options

Choose based on durability, maintenance, and detailing.

Timber cladding

- Warm, natural finish

- Needs ventilation and maintenance

- Best with rainscreen

Composite cladding

- Low maintenance

- Consistent appearance

- Still needs cavity

Brick slips

- Traditional look

- Requires careful substrate

- Heavier finish

Render

- Clean modern look

- Detailing critical at edges

- Check system compatibility

Window and door installation

Openings should be flashed and sealed with the SIP envelope in mind. Use tapes and membranes that bond to OSB and the chosen finish.

Comparison

Opening details

Keep water out and structure in.

Flashing sequence

- Sill flashing first

- Side flashings next

- Head flashing last

Housewrap or membrane

- Integrate with flashing

- Avoid reverse laps

- Seal to the panel skin

Problems with interior finishes

If interior finishes trap moisture, the SIP core suffers. Avoid vapour-closed layers without a drying path.

Pocket outriggers and structural edges

Openings, canopies, and lintels often need reinforcement. Detail the outriggers and fixings clearly so loads transfer safely.

Roofing finishes

SIP roofs accept many finishes, but ventilation and waterproof layers must be detailed correctly. Pay attention to eaves, ridge, and flashing.

Comparison

Roof finish options

Match the finish to the roof build-up.

Tiles

- Traditional UK finish

- Requires battens and venting

- Check roof loading

Metal roofing

- Lightweight

- Fast install

- Needs sound control

Single-ply

- Great for low pitches

- Requires careful detailing

- Protect from punctures

Specifying the fastening schedule

Fixings are structural, not cosmetic. Use the specified schedule to avoid squeaks, uplift issues, and warranty concerns.

Roof venting and ridge details

Roof venting prevents moisture build-up. Ridge details, including shingle ridging, must maintain airflow and keep water out.

Interior finishes

Plasterboard and service cavities often form the interior finish. This layer also contributes to fire resistance and airtightness.

Finish checklist

- Use a ventilated rain screen where appropriate.

- Detail flashing at every opening.

- Protect panel edges with trims or closures.

- Seal interior linings for airtightness.

- Follow the specified fixing schedule.

- Confirm roof venting paths.