Drawings that prevent delays

On site, the crew opens a pack and a window is 10mm out. A builder sees an extra crane day, the self-builder sees a delay, and the turnkey client sees another week of disruption. Layout drawings are the promise: every line becomes a panel in the factory. UltraSIPS uses a repeatable review checklist so errors are caught before manufacturing, not on the slab.

What layout drawings are for

Layout drawings are more than a snapshot. They are the bridge between design intent and the physical kit.

Comparison

Why layout drawings exist

Each purpose has a different audience.

Manufacturing

- Panel sizes, numbering, and CNC cut paths

- Spline types and rebates

- Exact opening positions

Installation

- Panel sequence and staging

- Crane pick order

- On-site fixings and sealant notes

Engineering review

- Load paths and point loads

- Wall, floor, and roof spans

- Connection details that carry structure

Compliance

- Building control sign-off

- Traceable revisions

- Clear references to calculations

Permit and building control review

Drawings are often reviewed for compliance before a kit is released. Make sure your layout set includes the references that building control expects: structural notes, insulation performance, and ventilation intent.

Reading panel numbering

Each panel has a unique ID. The order of IDs often matches the install sequence. Confirm this before delivery so the panels can be staged in order and the install day is smooth.

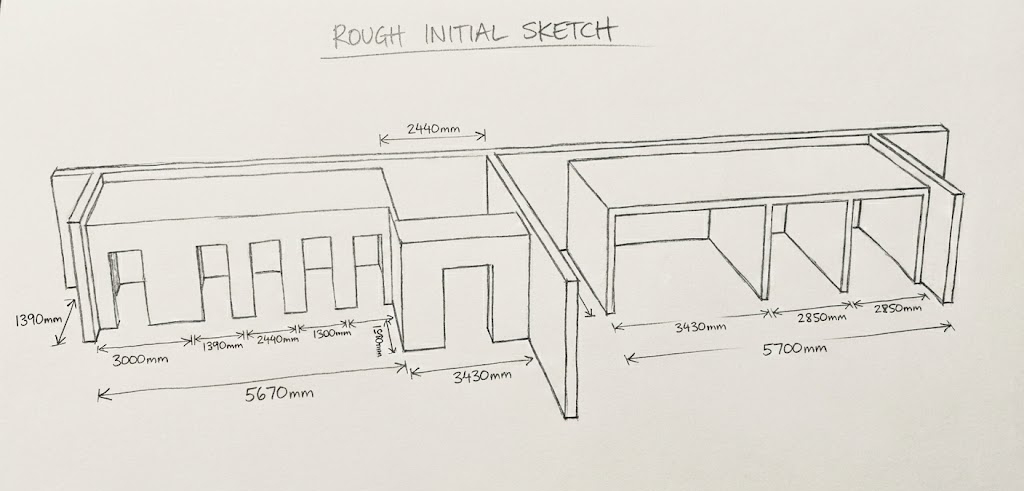

Isometric views and 3D cues

Isometric views are not decoration. They show how the kit is meant to fit together when floor plans and elevations feel abstract.

Comparison

2D vs 3D views

Use the view that answers the question fastest.

2D layouts

- Exact dimensions and set-out

- Opening sizes and positions

- Engineering callouts

Isometric views

- Visual build sequence

- Corner conditions and roof connections

- Useful for toolbox talks

SIP design translation

Layouts show how architectural intent becomes a panel pack. Check the grid, confirm offsets, and ensure openings stay on the module.

Comparison

Key design checks

These checks prevent the most expensive mistakes.

Grid alignment

- Panel widths stay on a 1200mm rhythm

- Avoids waste and on-site cutting

- Keeps splines consistent

Opening placement

- Sizes match the schedule

- Headers and posts are shown

- Clearance for frames and tolerances

Connection logic

- Spline types per joint

- Wall-to-floor bearing details

- Corner and junction solutions

Service strategy

- Routes for ducting and cabling

- No cutting through load paths

- Planned penetrations

Load design charts in the drawing set

Layout drawings should reference the span and load tables that informed the panel sizes. This makes the sign-off easier and avoids late engineering changes.

Over-engineering vs right-sizing

Some kits grow because every joint is treated like a heavy load. Use engineering where it adds value, not everywhere.

Comparison

Right-sizing the kit

Strength without unnecessary cost.

Over-engineered

- Extra posts at every opening

- Heavy splines where loads are light

- Thicker panels than needed

Right-sized

- Posts where loads demand them

- Spline choice matches span tables

- Panel thickness aligned with performance targets

Roof support structure

Roof structure is often the biggest source of confusion on site. Make sure ridge beams, purlins, and bearing lines are unambiguous in the drawing pack.

Comparison

Roof support types

Know what the roof is bearing on.

Ridge beam

- Clear structural line

- Panels bear directly

- Engineering must be shown

Purlins

- Intermediate supports

- Shorter panel spans

- Needs clear fixing detail

Truss support

- Hybrid systems

- More coordination

- Confirm load paths

Ventilation notes

Airtight shells need planned ventilation. Drawings should show intake and extract locations, service zones, and any back-venting or rainscreen details.

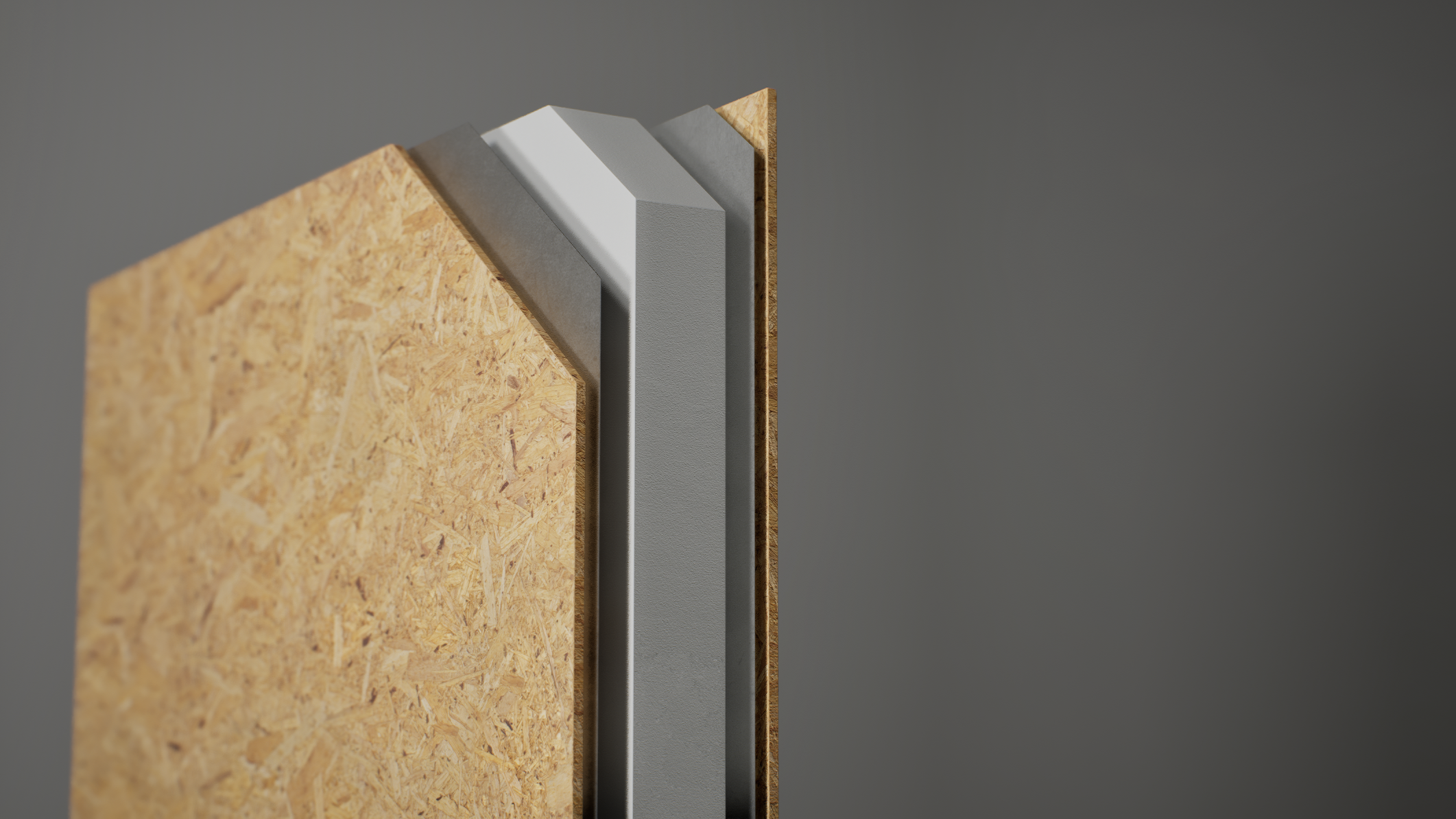

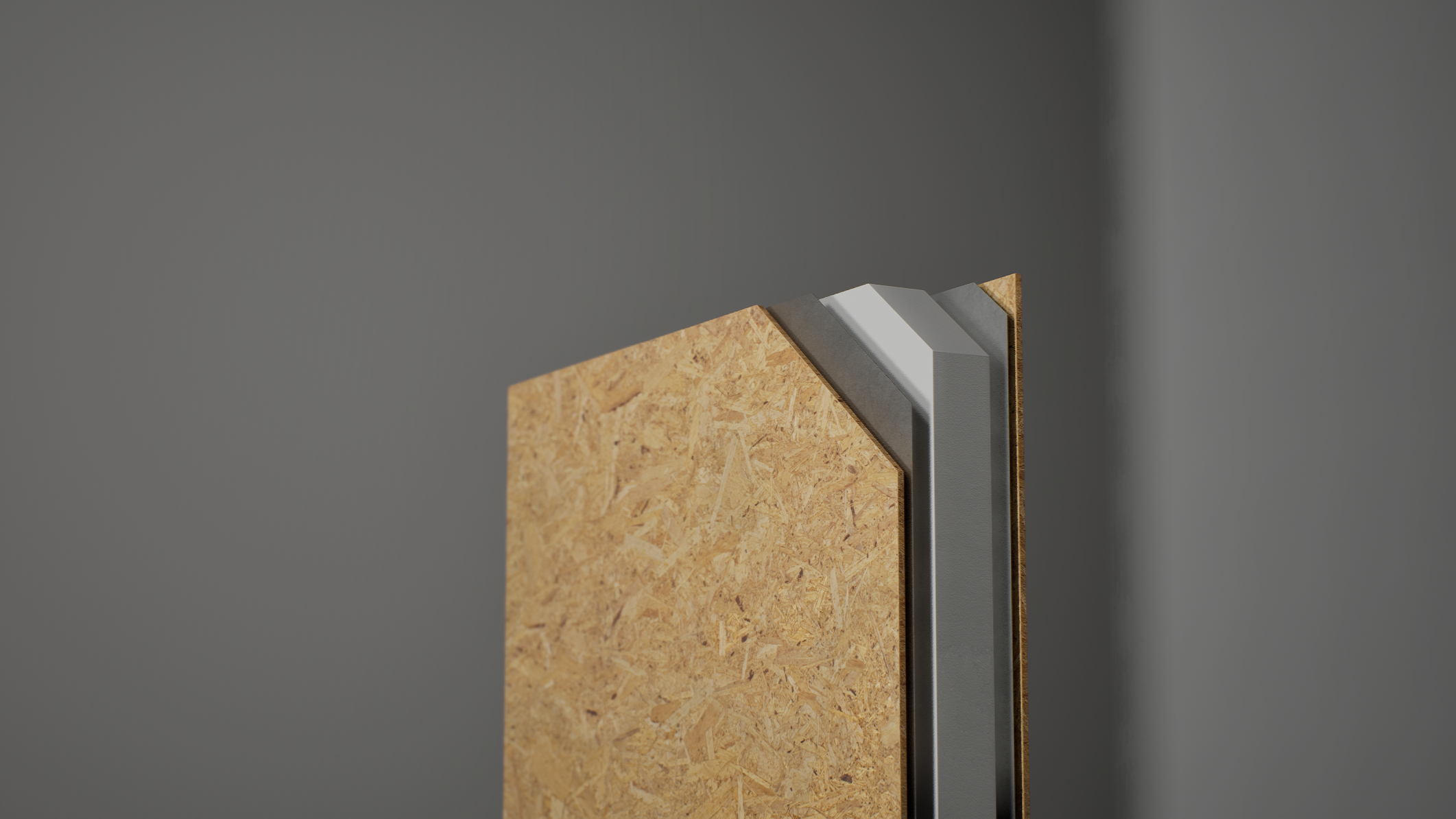

Splines and junctions

The drawing should show what spline is used at each joint. Make sure load-bearing joints get the correct detail and that any thermal breaks are noted.

Revision control

Every layout should include a revision number. Do not build from outdated drawings. Keep a single approved set for site use.

Layout review checklist

- Confirm panel sizes against the architectural plan.

- Verify all openings and structural supports.

- Check spline types at load-bearing joints.

- Confirm roof support lines and bearing points.

- Ensure ventilation notes are present and coordinated.

- Ensure revisions and dates match the final approval.