Imagine building with LEGO...

Start with the basics. Structural Insulated Panels (SIPs) are a high-performance building system for residential and light commercial construction.

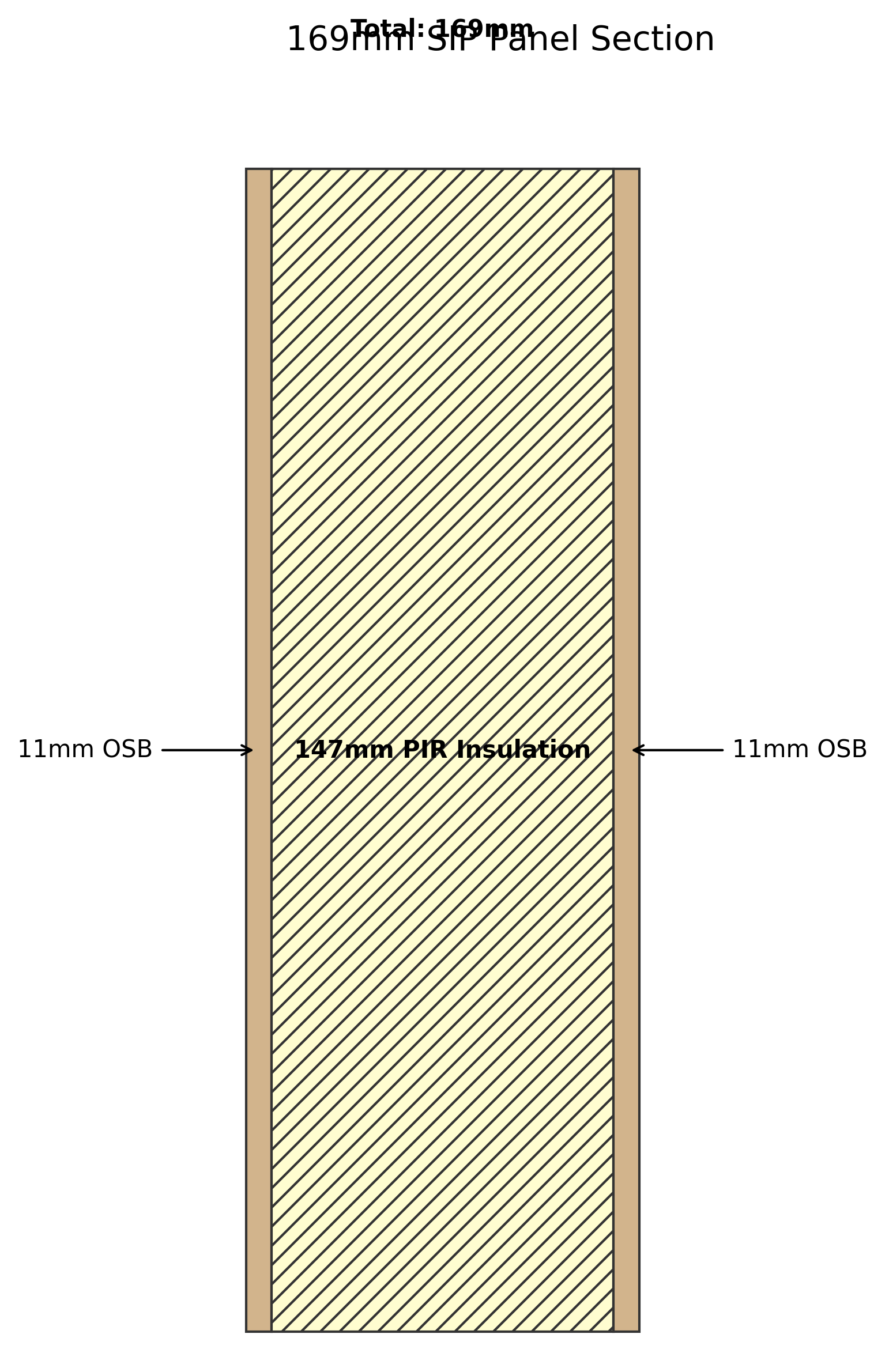

The panels consist of an insulating foam core sandwiched between two structural facings, typically Oriented Strand Board (OSB).

Structural

SIPs are load-bearing. They replace the timber frame or brick-and-block structure entirely.

Insulated

The insulation is built-in. No more stuffing rockwool between studs on a rainy Tuesday.

Why the UK is switching to SIPs

It comes down to physics. Traditional construction relies on multiple layers to achieve thermal performance. SIPs achieve it in one.

A Brief History

SIPs aren't new. They were actually developed in the 1930s at the Forest Products Laboratory in Madison, Wisconsin.

Frank Lloyd Wright used a form of them in his Usonian houses. But it wasn't until the 2000s that the UK market really woke up to them, driven by stricter energy targets (Part L) and the need for rapid housing.

Timeline of Innovation

- 1930sConcept developed in US Forest Products Lab.

- 1980sFirst mainstream adoption in US residential.

- 2000sUK adoption begins for self-builds.

- 2025UltraSIPS pushes performance to 0.15 W/m²K.

SIPs vs Brick & Block

The traditional way vs the modern way. Fight!

Speed

SIPs: Weather-tight shell in 3-5 days.

Brick: Weeks, dependent on British weather.

Space

SIPs: Thinner walls for same U-value = more floor space.

Brick: Thick cavities eat up your garden.

Precision

SIPs: Manufactured to ±2mm in a factory.

Brick: Relies on the skill of the brickie on a Friday afternoon.

Ease of Assembly

The "Slide & Lock" System

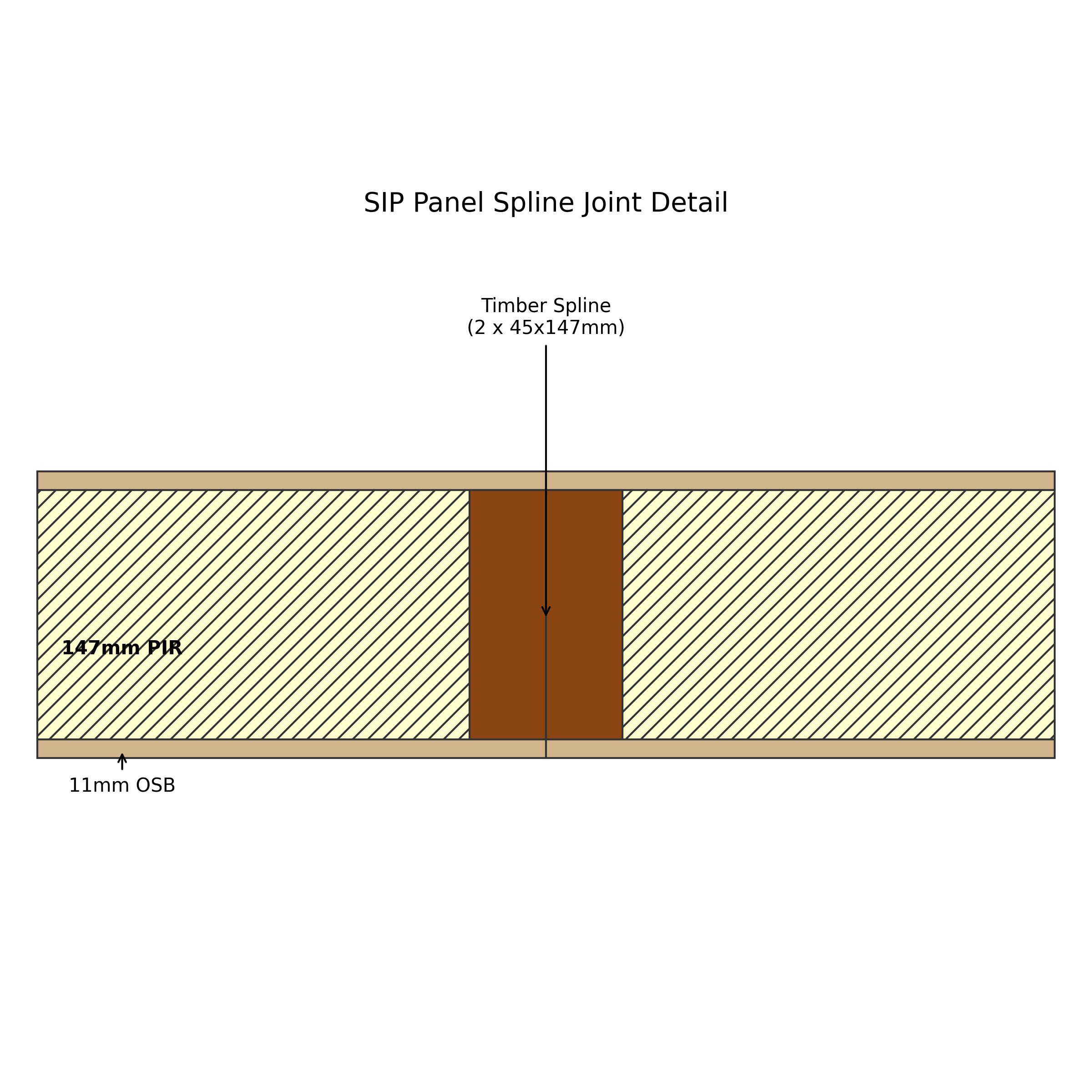

We use a Spline Connection. A thin strip of OSB (or insulated SIP spline) fits into the routed grooves of two vertically standing panels.

- Apply expanding adhesive.

- Insert the spline.

- Slide the panel.

- Nail to lock.

Technical Detail

Common Myths Busted

"They rot, don't they?"

No. The OSB facings are treated, and when properly wrapped in a breather membrane (like Tyvek) and clad, they last as long as traditional timber frame—60+ years easily.

"Can I hang a TV on it?"

Yes. Unlike plasterboard stud walls where you hunt for a stud, the entire wall is structural OSB. Screw into it anywhere. You could hang a gym on it.