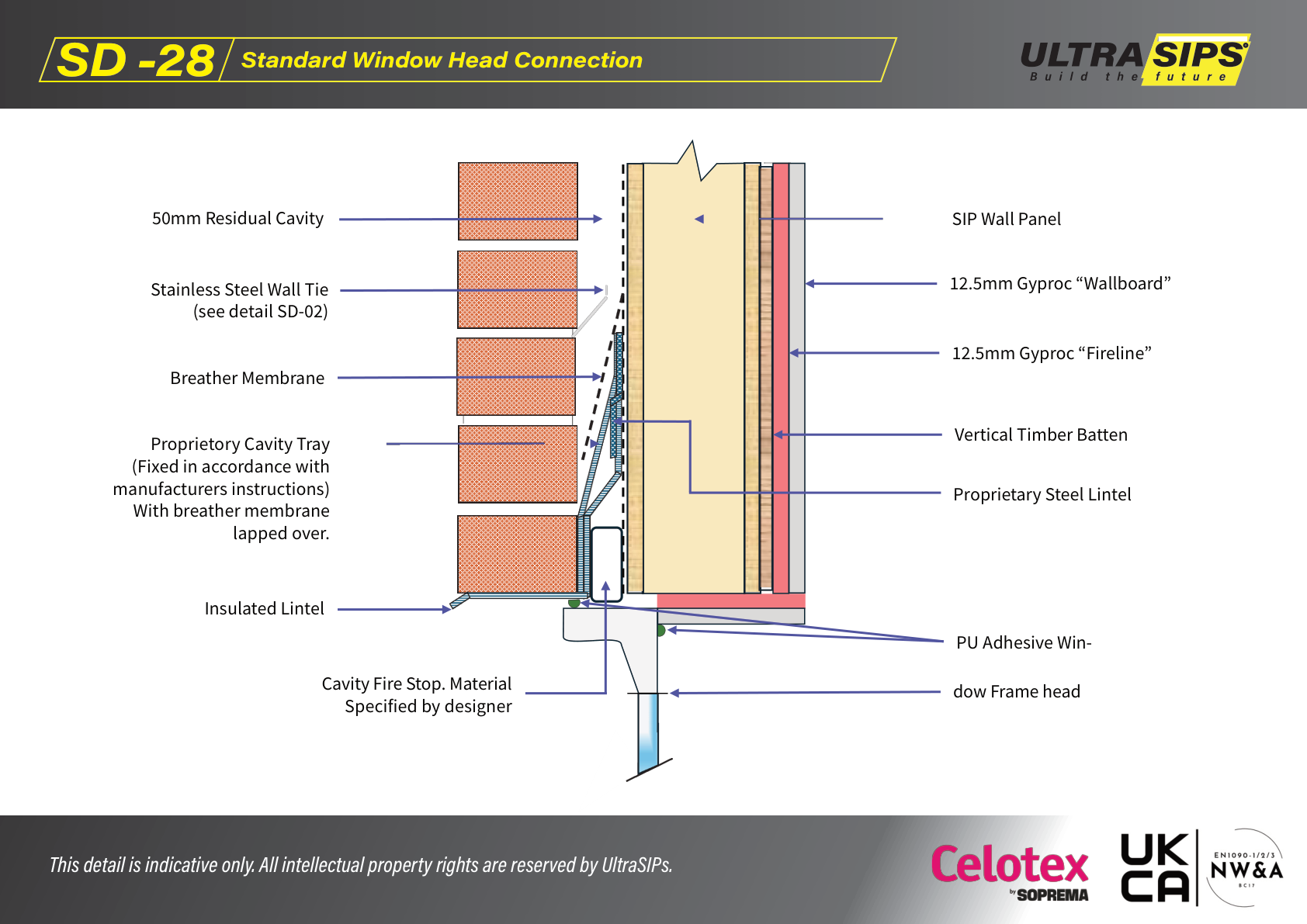

What this detail covers

- A typical window head build-up including lintel, cavity tray, and fire stopping.

- Maintaining membrane continuity and a managed drainage path.

Key steps

- Confirm lintel type (including any insulated lintel requirement) and cavity tray specification.

- Install cavity tray per manufacturer instructions and lap breather membrane over as required.

- Provide cavity fire stop material as specified and ensure internal lining boards meet the required FR rating.

Checks

- Cavity tray is installed with correct laps/ends to manage water.

- Fire stopping is continuous at the head.

- Window fixing zones and tolerances are maintained.

Common mistakes

- Missing cavity tray end dams/closures (water tracks into the wall).

- Cutting membranes after the fact and leaving unsealed laps.

Indicative only: always follow the engineer’s fixing schedule and the project drawings.