What this detail covers

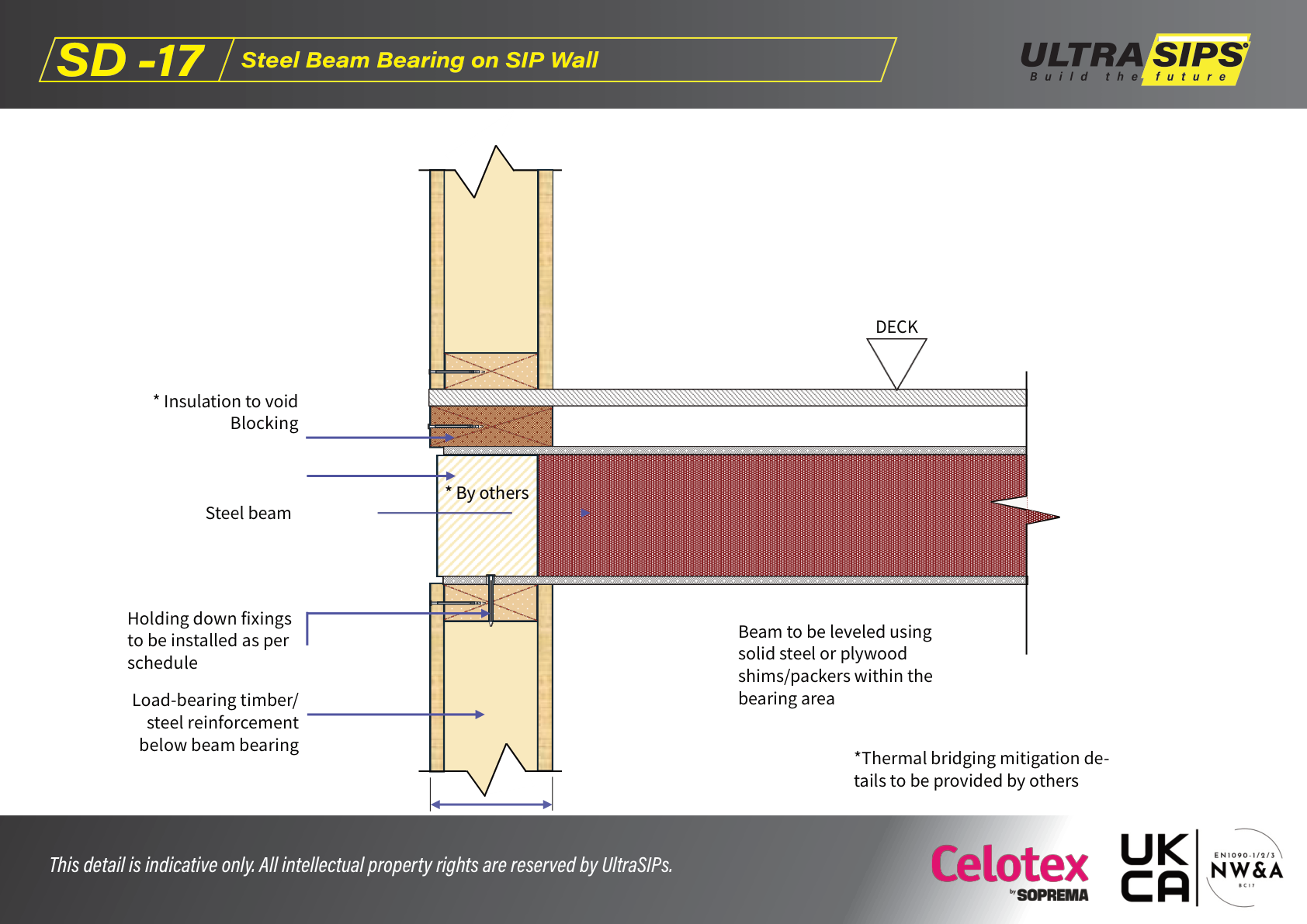

- A typical bearing arrangement where a steel beam bears on/into a SIP wall.

- Where holding down fixings and reinforcement may be required.

Key steps

- Confirm beam size, bearing length, and pocket position from the engineer’s drawings.

- Install reinforcement/bearing pieces as shown and fix to schedule.

- Level the beam using solid steel or plywood shims/packers within the bearing area (as specified).

- Coordinate any thermal-bridging mitigation detailing required by the project.

Checks

- Beam has full bearing and is level before the floor/roof build-up continues.

- Hold-down fixings are installed to the schedule.

Common mistakes

- Using compressible packers that settle over time.

- Leaving the bearing zone uninsulated/untreated where the spec requires it.

Indicative only: always follow the engineer’s fixing schedule and the project drawings.