What this detail covers

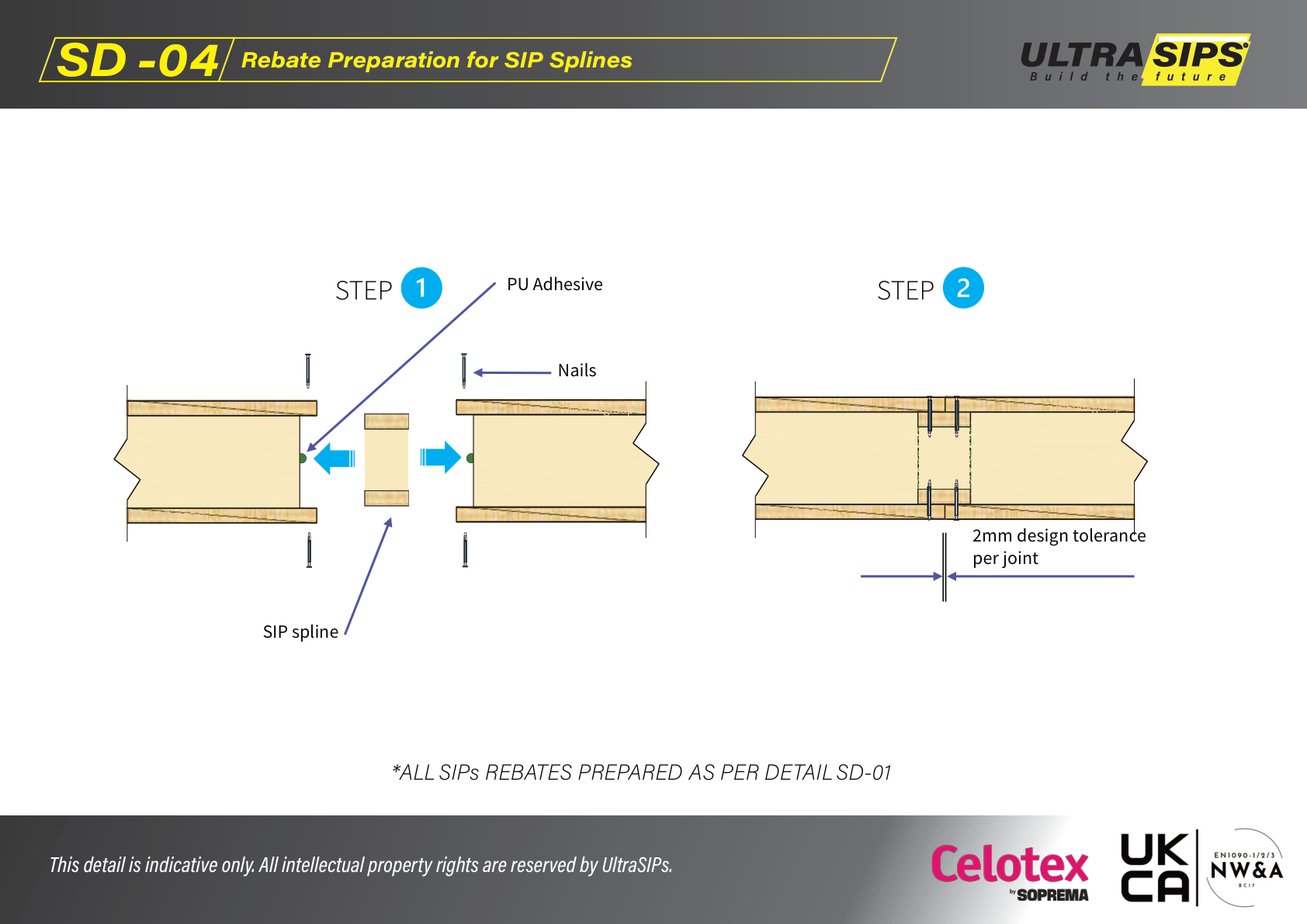

- Connecting panels using a SIP spline.

- The intended design tolerance per joint (typically ~2mm) so joints close correctly.

Key steps

- Apply PU adhesive to the mating faces as shown.

- Install the SIP spline and bring panels together.

- Fix as specified (often nails/screws per schedule) while keeping the joint straight.

Checks

- Joint closes tight without “springing” or forcing panels out of plumb.

- Adhesive is continuous along the full joint line.

- Tolerance is respected so cumulative errors don’t build up across the elevation.

Common mistakes

- Forcing tight joints when the issue is alignment/tolerance earlier in the run.

- Missing adhesive continuity at panel ends.

Indicative only: always follow the engineer’s fixing schedule and the project drawings.