What this detail covers

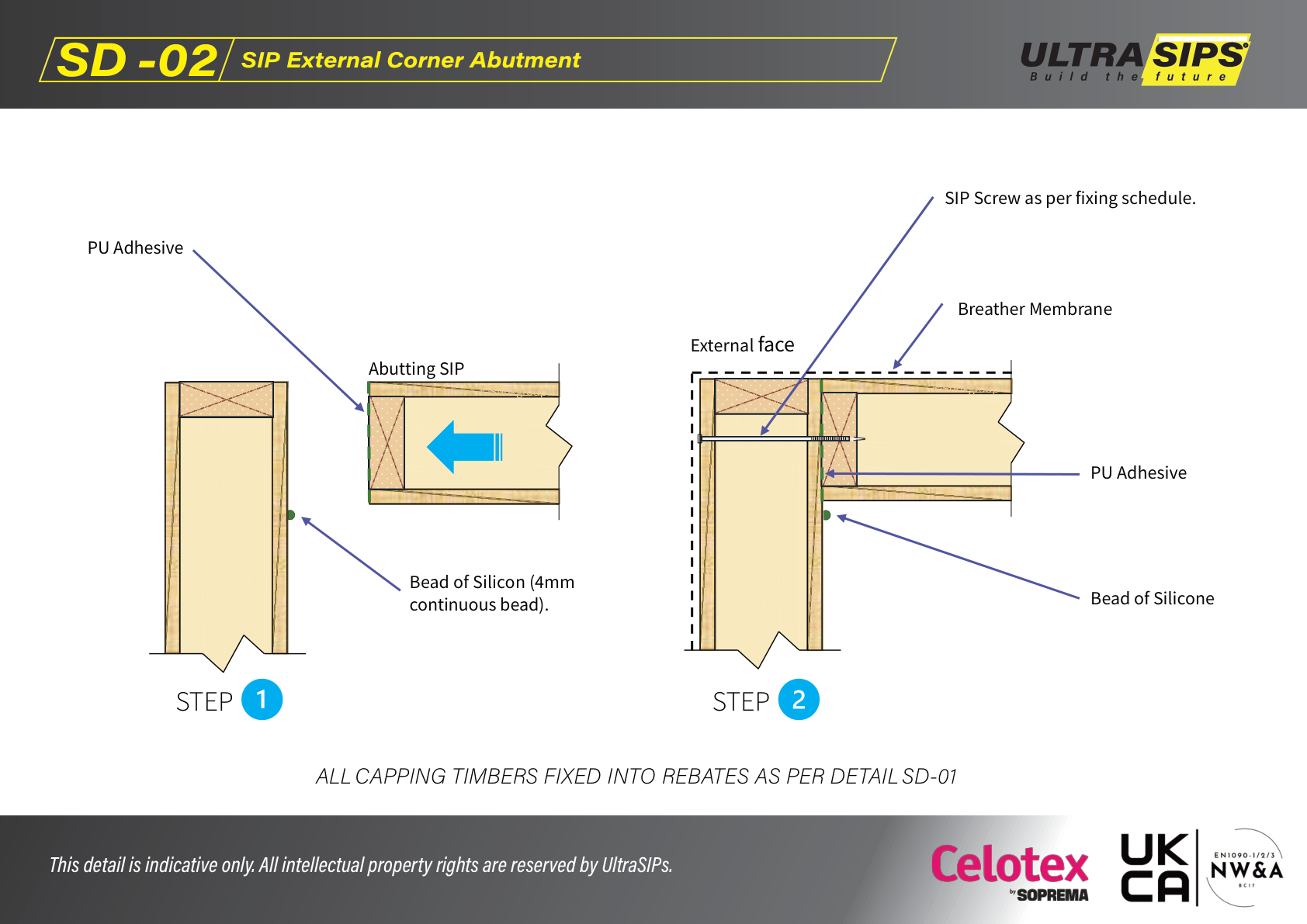

- The joint between two SIP wall panels at an external corner.

- Airtight/watertight sealing lines before the external membrane/cladding.

Key steps

- Apply PU adhesive to the mating faces as shown.

- Run a continuous bead of silicone (typically ~4mm continuous bead) at the shown seal line.

- Bring panels together and fix with SIP screws as per the fixing schedule.

- Maintain breather membrane continuity on the external face per the wall build-up.

Checks

- Corner is plumb/square and pulled tight with no visible gaps.

- Sealant bead is continuous (no breaks at the corner).

- External membranes lap correctly and remain unpunctured where required.

Common mistakes

- “Spot” sealant instead of a continuous bead.

- Over-driving fixings causing local crushing/gaps.

Indicative only: always follow the engineer’s fixing schedule and the project drawings.